Peking University, June 9, 2020: High-performance advanced composite materials integrating high stiffness, strength, and excellent damping performance are in urgent demands in aerospace, energy, high-speed transportation, and other fields. However, it is difficult for traditional damping materials to excel in both damping performance and those static mechanical properties mentioned above. In contrast, the biological materials in nature achieve the coexistence of superior static and damping properties through sophisticated microstructure design. For example, suture tessellations of different length scales are widely found in biological materials such as animal skulls, woodpecker beaks, turtle shells, purslane seeds, etc.

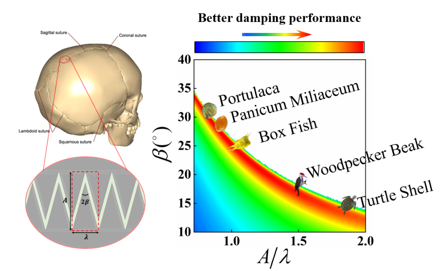

Figure 1. The theoretical model predictions suggest that sutural structures found in a number of natural lives have evolved to their optimal geometries to achieve the best damping performance.

Recently, the research team of Professor Wei Xiaoding in the Department of Mechanics and Engineering Science published their theoretical studies on the effect of suture structure on the energy dissipation of biocomposites in the Journal of the Mechanics and Physics of Solids (https://doi.org/10.1016/j.jmps.2020.104010). Their work establishes the relationship between the sutural geometry and damping performance. It shows how biomaterials in nature assemble the structural load-bearing units delicately through the sutural interfaces to realize the simultaneous optimization of excellent load-bearing capability and dynamic energy dissipation performance. The theory can explain how different biological materials have evolved suture angles and amplitudes of different scales during the long evolutionary process (Figure 1).

The team further synthesized a bioinspired composite with sutural interfaces through a multi-material 3D printer. Experiments show that the bioinspired design achieves an outstanding damping performance while having an excellent load-bearing capacity. The outcome from this study can provide valuable guidance to the design and manufacture of a new generation of advanced structural composite materials with outstanding static and dynamic mechanical properties.

This research was supported by the National Natural Science Foundation of China, the National Key R & D Program, and Beijing Innovation Center for Engineering Science and Advanced Technology at Peking University.

Source: College of Engineering, Peking University